Many European and American countries have specific requirements for the use of safety locks. The OSHA “Occupational Safety and Health Management Regulations” Hazardous Capability Control Regulations clearly stipulates that employers must establish safety procedures and lock devices according to the procedures. It is installed in the energy isolation device to be listed or the equipment is stopped to prevent accidents, starting or the release of starting energy, so as to avoid manufacturing employees.

What is a safety lock

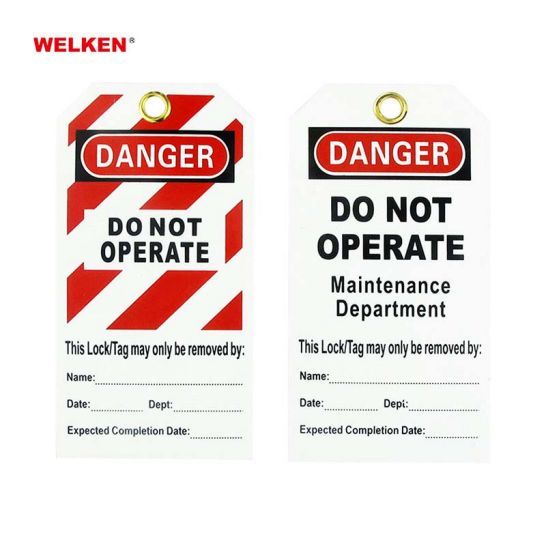

Safety locks are a kind of locks. It is to ensure that the equipment energy is absolutely shut down and the equipment is kept in a safe state. Locking can prevent accidental operation of the equipment, causing injury or death. Another purpose is to serve as a warning.

Why use a safety lock

According to the basic standard to prevent others from misoperation, use targeted mechanical tools, and when the body or a certain part of the body extends into the machine to work, it will be locked when the operation is dangerous due to the misoperation of others. In this way, when the employee is inside the machine, it is impossible to start the machine, and it will not cause accidental injury. Only when employees come out of the machine and unlock the lock by themselves, can the machine be started. If there is no safety lock, it is easy for other employees to turn on the equipment by mistake, causing serious personal injury. Even with “warning signs”, there are often cases of inadvertent attention.

When to use the safety lock

1. To prevent the sudden start of the equipment, a safety lock should be used to lock and tag out

2. To prevent the sudden release of residual power, it is best to use a safety lock to lock

3. When it is necessary to remove or pass through protective devices or other safety facilities, safety locks should be used;

4. Electrical maintenance personnel should use safety locks for circuit breakers when performing circuit maintenance;

5. Machine maintenance personnel should use safety locks for the machine switch buttons when cleaning or lubricating machines with moving parts

6. Maintenance personnel should use safety locks for the pneumatic devices of mechanical equipment when troubleshooting mechanical failures.

Marst lock classification

Safety padlocks, safety tags and signs, electrical accident prevention devices, valve accident prevention devices, buckle accident prevention devices, steel cable accident prevention devices, lock management stations, combined management packages, safety lock hangers, etc.

Marst Safety Equipment (Tianjin) Co., Ltd. is a professional manufacturer of personal accident prevention devices focusing on R&D, production and sales. The main products involve safety locks, eye washers, etc. The company has independent intellectual property rights and a professional product research and development team, committed to serving a complete set of solutions for personal protection in petroleum, chemical, electric power, manufacturing, industrial and mining.

We are always based on the user experience, adhering to the concept of novel design, simple structure, convenient use, and excellent selection of materials. We take safety and care for life as our corporate purpose, continuous improvement, continuous improvement, continuous innovation, and professional and high-quality safety protection products. Serve society and serve safety!

Post time: Jul-14-2021